Automation is no longer a thing of the distant future—it’s the reality we live in now

Lately, you can’t go a day without hearing the word "automation" in the news.

From Tesla’s self-driving tech to drone deliveries and AI-powered customer service, futuristic technologies that once felt like science fiction are now part of our everyday lives.

And I’ve personally felt this shift.

What caught my attention the most was the topic of logistics robots.

It wasn’t just curiosity—it felt personal.

A few years ago, my younger brother worked part-time in a U.S. warehouse.

What started as a way to make some pocket money turned into a physically and emotionally draining experience.

Eventually, he collapsed from repeatedly lifting heavy packages and decided to quit.

I still remember what he told me afterward:

“This isn’t work for humans. Machines should be doing this.”

That wasn’t just a complaint—it was a quiet signal of a future already taking shape.

Then recently, I came across an article about Amazon reducing its reliance on human labor by introducing AI and robots into its warehouses.

And at that moment, I felt a mix of emotions—hope, concern, excitement, and unease.

“Machines are finally doing the work my brother said they should be doing…”

But then I wondered, “What happens to all the human jobs?”

Still, as a customer, I can’t deny the appeal of speed and convenience that automation brings.

After living in Korea, where next-day delivery is the norm, the U.S. logistics system felt painfully slow.

In Korea, you can order something at 3 p.m. and receive it the next morning.

It’s fast, accurate, and incredibly reliable.

So, when I discovered Amazon Prime, I was genuinely impressed.

It quickly became something I couldn’t live without in the U.S.

That’s when I asked myself:

“How does Amazon deliver so fast?”

“What kind of technology and strategy make this possible?”

That curiosity led me to dive deep into Amazon’s logistics automation system.

U.S. Logistics Is Entering the Era of Robotics

After COVID-19, the explosion in online shopping in the U.S. made logistics efficiency more important than ever.

The challenge was clear: deliver faster, more accurately, and at a lower cost—all at once.

Traditional logistics models, built on manual labor and regional distribution, were no longer scalable in the age of real-time commerce. Retailers needed to rethink not just how goods move, but how decisions are made in milliseconds across supply chains.

In response, the U.S. government passed the Infrastructure Investment and Jobs Act (IIJA), allocating a staggering $1.2 trillion to modernize and automate the nation’s infrastructure, including logistics.

The IIJA allocated $1.2 trillion for nationwide infrastructure modernization, with a portion directed toward improving logistics systems.

This included upgrades to port technology, highway automation, and last-mile delivery optimization—building the digital backbone required for 21st-century commerce.

At the center of this transformation is none other than Amazon.

Amazon began investing in logistics automation over a decade ago and is now the frontrunner in smart warehousing in the U.S.

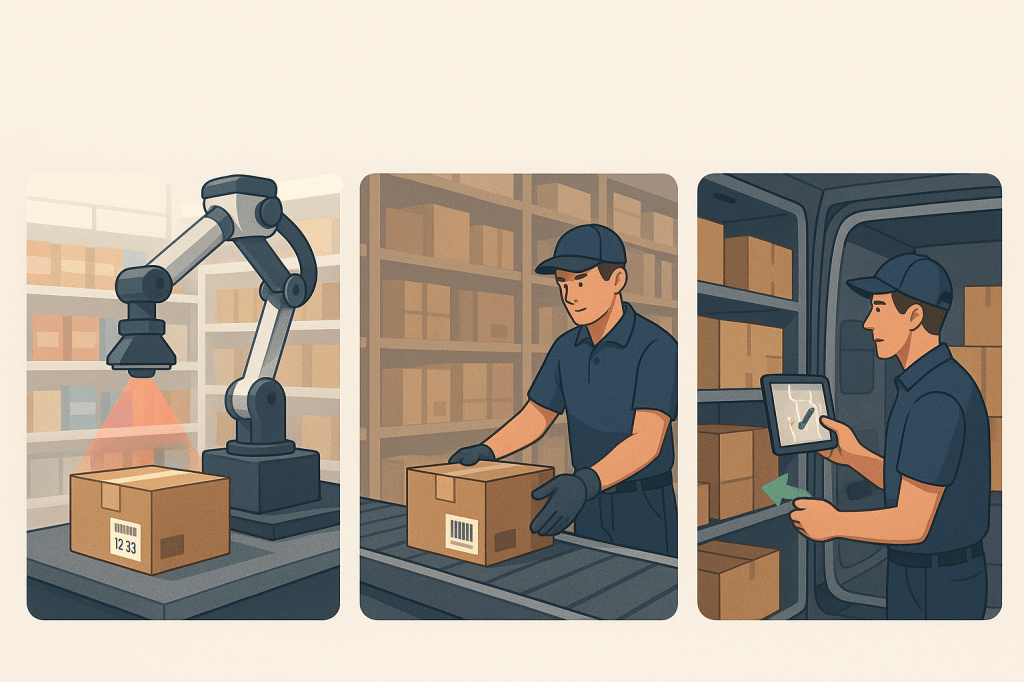

From Kiva to Sparrow: Amazon’s Army of Robots

Amazon’s robotics journey began in 2012 with its acquisition of Kiva Systems, a startup that revolutionized warehouse operations.

Instead of workers walking miles each day to retrieve products, robots now bring mobile shelving units directly to the picker’s station—drastically reducing idle time and physical strain.

Since then, Amazon has continuously developed and deployed more advanced robots, each targeting a specific bottleneck in the fulfillment process:

- Proteus: An autonomous mobile robot that can safely navigate warehouse floors and transport goods without human intervention. It’s designed to operate freely in environments shared with people—unlike older robots confined to cages.

- Cardinal: A fixed robotic arm that uses computer vision and machine learning to lift, scan, and route packages of various weights and shapes. This reduces human error and helps process thousands of items per hour.

- Sparrow: The most advanced picking robot to date. It can identify, grasp, and move millions of different products—ranging from soft clothing to boxed electronics. It represents a major leap toward full item-level automation.

These robots aren’t just isolated tools.

They are nodes in a larger system—working together under intelligent coordination, enabling high throughput while reducing human fatigue and injury.

The Real Power Lies in the ‘Invisible Software’

While the physical machines are impressive, the real power lies in the software behind the scenes.

Amazon’s fulfillment centers operate like living organisms. AI-powered decision engines orchestrate robots, inventory, and human workflows in real time. This coordination is possible thanks to a suite of proprietary systems:

- Vision System: Uses computer vision to accurately identify products, barcodes, and shelf locations—improving inventory precision and reducing errors.

- VASS (Vision-Assisted Sortation System): Allows workers to sort packages quickly without looking at digital displays, thanks to image-guided lighting and smart scanning.

- VAPR (Visual Assisted Picking for Routes): Guides drivers to find the right package faster and plan efficient delivery sequences, reducing idle time and fuel use.

These systems digest millions of data points per second, learning from every movement, scan, and delivery delay to continuously optimize operations.

By integrating AI and robotics, Amazon has created a logistics platform that is not only efficient but adaptive—capable of responding to sudden demand spikes or route disruptions in near real time.

Real Results: The Numbers Speak for Themselves

According to Amazon’s internal report (Amazon Robotics White Paper, 2023), the introduction of the Sparrow system led to a 40% reduction in injury rates at a specific fulfillment center.

That kind of impact is not just a win for productivity—it directly affects worker safety and long-term operational sustainability.

Other tangible benefits include:

- Lower employee turnover and higher job satisfaction

- 30 minutes saved per delivery route (based on VAPR system)

While these gains are promising, they also raise questions.

How will companies retrain workers displaced by automation?

Can smaller retailers afford to compete in a world defined by hyper-efficient logistics?

According to Custom Market Insights, the U.S. logistics automation market was valued at approximately $23.83 billion in 2024, with an expected compound annual growth rate (CAGR) of 10.4% through 2033.

Although Amazon’s exact market share is not publicly disclosed, the company operates with over 75,000 autonomous robots and ships more than 6.3 billion packages annually in the U.S. alone—surpassing even FedEx and UPS in total volume.

These figures reinforce Amazon’s dominant role not just as a participant, but as a driver of innovation and scale in the logistics automation sector.

🏢 Amazon Company Snapshot

| Item | Details |

|---|---|

| Founded | 1994 |

| Founder | Jeff Bezos |

| Headquarters | Seattle, Washington, USA |

| Core Businesses | E-commerce, AWS, AI & Robotics, Smart Logistics, Digital Content |

| Market Cap | Approx. $1.8 trillion (as of 2025) |

Conclusion: The Future Amazon Has Shown Us Is Becoming Everyone’s Present

Amazon is pioneering a new frontier in logistics, where robots, AI, and data are seamlessly integrated.

And this isn’t just a trend—it’s the new standard.

Automation isn’t coming someday.

It’s already inside our warehouses, on our delivery trucks, and in the packages we receive.

The one truth we should all remember:

📦 “Only companies that can deliver faster and more accurately will survive.”

Delivery speed and accuracy are becoming increasingly critical competitive factors, and companies that lead in these areas are more likely to gain market dominance.

Still, as automation grows, the industry must also consider inclusivity, digital literacy, and labor rights.

Efficiency shouldn’t come at the cost of equity.

And Amazon may already have the answer—or at least, a preview of what’s to come.

📌 If you found this post helpful, please share it!

📸 Need AI-generated images of Amazon robots in action? Leave a comment!

Have more topics you’re curious about? Let me know below. 😊

Leave a comment